Dearman Steps up As India Demands Clean Cold Chain

The United Nations is forecasting India’s population to have surpassed China by 2024, and to increase further to 1.5 billion by 2030.

This begs a fundamental question for the Indian government: how to ensure there is sufficient food for this huge population increase? It certainly highlights a chink in the Indian armour as the value of food lost to wastage across the country is a staggering US$13 billion every year.

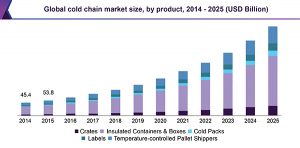

Today, less than 4% of India’s fresh produce passes through a cold chain. The refrigerated transport sector needed for a robust joined-up cold chain is rudimentary or non-existent, and that’s why in 2012, the government set up the National Centre for Cold Chain Development. Ministers estimate that the country must invest around US$15 billion to build integrated cold chains over the next five years and annual growth in the sector is expected to be around 25% per year, almost double the global average of 13.2%. India needs almost 3,000,000 TRUs to achieve European post-harvest loss prevention.

1. The Dearman solution

This presents an opportunity for Dearman. Despite the significant development predicted for its cold chain, India recognises it must do so cleanly to avoid contributing to its already significant air pollution problem. A recent World Health Organisation list highlighted that 11 out of the 12 most polluted cities in the world were in India and, as a result of the appalling pollution, the country sees 600,000 premature deaths every year. The growing backlash against diesel around the world has further underscored the need for clean alternative technologies.

At the heart of the Dearman system is the Dearman engine which is a novel piston engine driven by the expansion of liquid nitrogen (LiN) or liquid air, to produce clean cold power. The only emission from a Dearman engine is nitrogen, with no emissions of NOx, CO2 or particulates. Our award-winning transport refrigeration unit (TRU) application has been backed with funding from the UK government and has been successfully deployed by a number of major retailers; Marks & Spencer, Sainsbury’s, and Unilever. In fact, an article published by Unilever called its deployment of a Dearman TRU “a resounding success” and described the system as “revolutionary”.

2. The Dearman Transport Refrigeration Unit is the first to meet all environmental challenges – and set new industry performance standards – all without having to compromise on cost.

At Dearman, we believe we can be part of the solution for India. That is why we have rolled out a two-year project to further explore the refrigerated transport market, understand customer requirements, and develop a ‘ruggedised’ TRU and cryogenic system suitable for the Indian market. Working alongside the Department of Biotechnology in India, the Indian Institute of Technology Bombay, Cartwright Group and the University of Birmingham, we will also deploy a TRU on a transport vehicle with an Indian customer to showcase our technology and gather valuable data on its application.

India currently has just 9,000 refrigerated vehicles and conservative forecasts suggest that the TRU market demand will be nearly 250,000 vehicles by 2025. More bullish forecasts however, based on TRU demands in Europe and accounting for increased urbanisation and affluence in India, suggest TRU demand could be at least 750,000 vehicles.

Our 24-month project is a chance to demonstrate a range of major potential benefits for India: supporting manufacturing, boosting green jobs, supporting Prime Minister Narendra Modi’s ambition to double farmers’ incomes, helping to clean up India’s air and support improved health outcomes. And of course, reduce India’s significant food loss to help feed its growing population. The Dearman solution is ground-breaking not only because it can lead to all those outcomes, but because it will do so cleanly. India’s cold chain is clearly ripe for significant expansion and Dearman is determined to be at the heart of that. By Shezad Suleman, Project Manager, Dearman Engine Company. Source: dearman.co.uk