Article 6

Pengaturan suhu parsel agar tetap pada kisaran suhu yang diperbolehkan sesuai dengan persyaratan mutu produk segar selama pengiriman, telah terstandardisasi dan SNI ISO 23412 telah mengaturnya yang dibatasi untuk pengiriman transportasi darat dan yang menggunakan refrigeran aktif. Digitalisasi diperlukan agar dapat terjadi komunikasi aktif antara penyedia layanan dan penggunanya (konsumen akhir). Data dari rekaman suhu selama pengiriman, tersimpan baik dalam satu alat penyimpanan data (data logger).

Standar pengiriman ini terus dapat memonitor suhu produk secara real time, 10-15 menit sekali, baik pada saat penjemputan produk, pengumpulannya (hub-storage) untuk memudahkan area dan keseragaman suhu produk dan dilanjutkan ke pengiriman akhir ke konsumen.

Di dalam monitor suhu parsel, sebaiknya bagi penyedia jasa mempersyaratkan kemasan yang baik yang disiapkan oleh pengguna (konsumen) sehingga dapat menjamin produk tidak rusak selama pengiriman.

Kegiatan pre-cooling boks berinsulasi hingga mencapai suhu yang sesuai dengan suhu produk yang akan dikirim, akan menjamin minimalisasi fluktuasi suhu produk dan masih masuk dalam persyaratan kisaran suhu. Pre-cooling sebaiknya dapat dilakukan pada 3 (tiga) penetapam suhu pengiriman, yaitu: frozen (-10 sd -20) derajat Celsius, chilled (-5 sd +10) derajat Celcius, dan air conditioning (+15 sd +25) derajat Celcius.

Diperlukan standar prousedur pengiriman untuk disiplin dalam pekerjaan dan waktu bagi pelaksana tugas selama proses bongkar muat dan pengiriman berjalan

COOL PARCEL DELIVERY

Setting the parcel temperature to remain within the permissible temperature range in accordance with fresh product quality requirements during delivery has been standardized and SNI ISO 23412 has regulated it which is limited to land transportation deliveries and those using active refrigerants. Digitalization is needed so that active communication can occur between service providers and their users (end consumers). Data from temperature recording during shipping is stored in one data storage device (data logger).

This delivery standard can continuously monitor product temperature in real time, every 10-15 minutes, both during product pick-up and collection (hub-storage) to facilitate area and product temperature uniformity and continue to final delivery to consumers.

In monitoring parcel temperatures, it is best for service providers to require good packaging prepared by the user (consumer) so that they can guarantee that the product is not damaged during delivery.

The activity of pre-cooling the insulated box until it reaches a temperature that is appropriate to the temperature of the product to be sent, will ensure that product temperature fluctuations are minimized and that it still falls within the temperature range requirements. Pre-cooling should be carried out at 3 (three) delivery temperature settings, namely: frozen (-10 to -20) degrees Celsius, chilled (-5 to +10) degrees Celsius, and air conditioning (+15 to +25) degrees Celsius.

Standard delivery procedures are required for discipline in work and time for task performers during the loading and unloading and delivery processes

Article 5.

TEKNOLOGI PEMBEKUAN BERKUALITAS TINGGI

Teknologi ini menggunakan peralatan, apa yang dinamakan rapid freezer. Pembekuan yang menggunakan cairan merupakan teknologi pembekuan kekinian.

Teknologi pembekuan dengan menggunakan cairan nitrogen ataupun air garam alkohol dapat membekukan makanan dengan cepat. Pembekuan cepat sebelumnya adalah dengan mengalirkan udara dingin bersuhu -35 °C sd -40 °C memerlukan waktu 6 – 8 jam. Sedangkan pembekuan yang menggunakan cairan ini yang bersuhu hingga -120 °C hanya memerlukan waktu 1 – 2 jam saja. Cairan yang digunakan menghasilkan sekitar 20 kali lebih konduktif termal daripada gas.

Makanan mulai membeku pada suhu -1 °C dan hampir sepenuhnya membeku pada suhu -5 °C. Pada kisaran suhu inilah akan terbentuk kristal es pada makanan. Menggunakan cairan pada pembekuan cepat (rapid freezer), kristal es yang terbentuk sangat kecil ukurannya (5 mikron). Sedangkan pada pembekuan cepat udara dingin (blast freezer) kristal es yang terbentuk berukuran sekitar 50 – 100 mikron, pada pembekuan lambat udara dingin (suhu -20 °C) kristal es yang terbentuk berukuran lebih besar dari 300 mikron. Semakin besar kristal es yang terbentuk akan lebih besar pengaruhnya kepada kerusakan sel makanan. Batas aman pembekuan makanan adalah pembekuan cepat udara dingin (suhu -40 °C). Harap dapat membedakan pembekuan makanan dengan peyimpanan dingin makanan.

Ada beberapa contoh produk bernilai ekonomi tinggi yang harganya lebih mahal jika dibekukan dengan cepat berkualtas tinggi, seperti red meat, ikan tuna, atapun buah durian.

Buah durian populer di dunia. Negara China yang penduduknya menyukai durian, mengimpor dari beberapa negara ASEAN, seperti Vietnam (segar), Thailand (beku dan segar), Malaysia (beku) ataupun ada sedikit dari Indonesia. Pada tahun 2022 negara China mengimpor sebanyak 900 ribu ton setahunnya. Khususnya Malaysia, durian hanya dipanen saat sudah 100% matang. Sedangkan negara lainnya tidak demikian. Dengan tingkat kematangan tersebut, Malaysia membekukan durian dengan pembekuan cepat kualitas tinggi menggunakan nitrogen cair yang dapat menjaga kualitas seperti kondisi baru petik 100% matang. Karena itulah harga durian yang berasal dari Malaysia lebih tinggi karena selain rasa, kesegaran buahnya terjaga.

Article 4.

TOP ADVICE FROM COLD CHAIN TRANSPORTATION (Point of Best Practices Guide)

1. GET IN WRITING

Agree in writing the expectation of the customer/shipper before taking a job. This includes specifying expectations for:

- Packaging

- Stowage

- Temperature management

- Sanitation

- Handling

2. USE TECHNOLOGY BUT HAVE BACK-UPS

Technology provides significant time and cost savings and ensures transparancy at a level not possible 20 years ago – wherever possible, invest in real-time:

- Load tracking

- Temperature monitoring

- Record keeping

BUT do not use technology as a substitute for visual checks, driver use training because systems fail sometimes

3. KEEP IT COOL

Leave “Nothing to Change” when managing temperature on collection, delivery and whilst on thr move – ensure:

- Equipment is to the necessary standard and working correctly

- Vehicles are pre-cooled before loading

- Air circulation is possible when loaded

4. FOCUS ON RISK

Food safety is based on awareness and control of risks. Stay ahead of the most prominent risks:

- Cross contamination

- Allergen exposure

- Food crimes (like fraud or malicious contamination)

Article 3.

5 WAYS TO REDUCE ENERGY COST IN COLD STORAGE WAREHOUSE

Improve energy efficiency by using floating suction pressure control to continually optimize suction pressure set points based on cooling requirements. Optimize the freezer temperature set point to raise temperatures in refrigerated spaces while maintaining safe product temperatures.

Minimizing air infiltration through open door and loading docks is a cost-effective way to improve energy efficiency. Repair malfunctioning freezer doors and strip curtains to decrease air infiltration from outdoors.

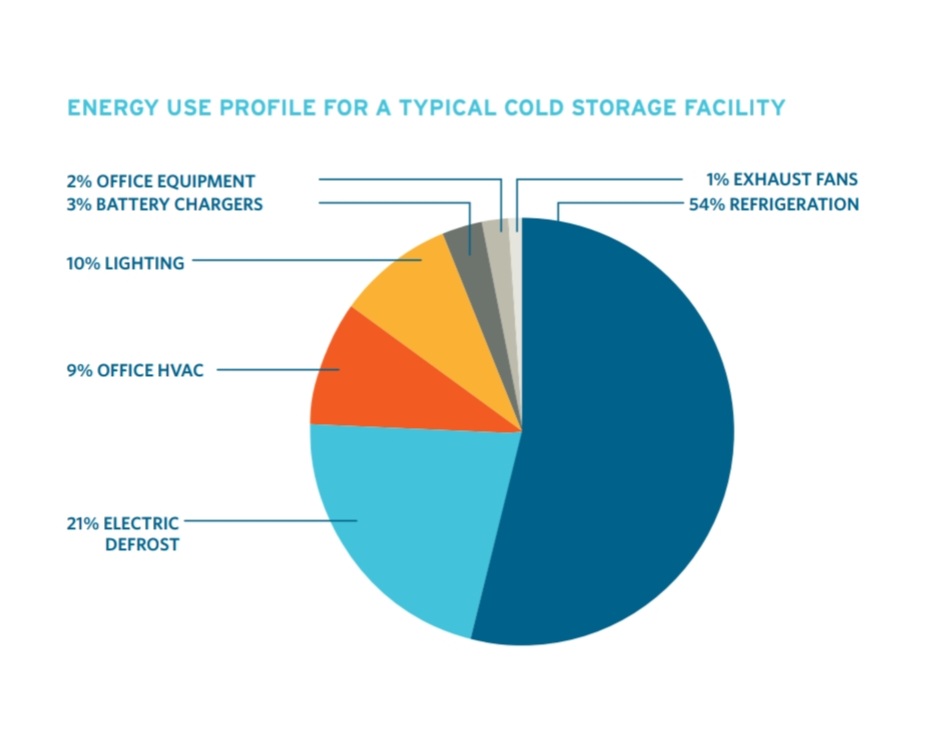

One of the highest operating costs for refrigerated and cold storage facilities is energy. Massive amounts of energy are needed to maintain stable temperatures, especially in storage facilities specializing in perishable refrigerated and frozen foods.

Managers and operators of these facilities are constantly looking for ways to balance energy costs and temperature stability. The best solution lies in leveraging new technologies and modern equipment that guarantee the product is protected and your bottom line is not affected.

Let’s look at a few strategies for lowering energy costs while keeping the required operational temperatures stable:

- Maximize Equipment’s Design Efficiency

Each refrigeration system features an ideal output that yields the highest efficiency when need be. It is common for operators to run their equipment below the system’s peak design efficiency so that they maintain a stable temperature and cut energy consumption. However, to optimize efficiency, you should strive to run your system with a “fully loaded” design output. Typically, the systems running at 100 percent of their peak for more time tend to idle for more prolonged periods resulting in lower power consumption and reduced costs. - Prioritize High-Speed Opening and Closing Cold Storage Doors

This measure might seem obvious, but many facilities fail to track the performance of their doors as often as they should. When it comes to design features, you should go with modern high-performance industrial freezer and cooler doors. Such doors are uniquely designed and customized with energy efficiency in mind. The doors are made using energy-efficient materials with higher R-values to reduce heat loss due to conduction.

- The largest energy load in a cold storage facility is from infiltration of warm/humid outdoor air and leakage of refrigerated air to the outside atmosphere. An improperly sealed door will let the cold air escape and force the refrigeration units to work harder to maintain food quality. High-performance freezer and cooler doors come with uniquely designed seals that reduce air infiltration and exfiltration. These seals are mounted along the perimeter of the opening and provide tight sealing when you close the doors.

- In addition to needing higher R-values and tight seals, it is important to determine the opening and closing speed of your refrigerated doors. A door that opens and closes slowly lets in large amounts of cold air, resulting in high energy loss. Industrial high-speed doors operate at opening speeds of up to 100” per second. Cold storage doors operating at these speeds will help systems maintain their energy efficiency. If you are using older doors that are slow, poorly insulated, or leaking air, it may be time to install high-speed freezer and cooler doors that offer better energy efficiency.

3. Increase Efficiency with More Nighttime Refrigeration

You can increase your refrigeration system efficiency by running more nighttime operations than daytime ones. Refrigeration equipment emits more heat into the atmosphere when the outside temperatures are cooler, and thus a system that runs at night offers better energy efficiency. Once you install a Thermal Energy System (TES) into your equipment, the cold generated during the nighttime will be stored and used to supplement daytime cooling. Essentially, this will help you reduce refrigeration run time during the day.

4. Use TES Systems to Limit Run Time

There is a high chance you are already minimizing your equipment run time using standard energy-saving strategies. However, you are constrained by operational limits when pushing such a strategy. Ideally, continuous fluctuating heat infiltration and seasonality in daily operations can complicate the traditional methods used to minimize run time. So how best can you minimize your equipment run time? Well, leverage modern Thermal Energy Storage technologies and systems that allow for a limited run time strategy. TES systems enable your cooling equipment to idle for an extensive duration of over 10 hours without posing any risks to food quality. Once installed, such systems absorb a high percentage of heat infiltration, thus reducing runtime, kilowatt-hours, and energy costs.

5. Take Advantage of Off-Pick Pricing

Most power utilities offer off-peak period pricing designed to encourage large energy consumers to run most of their operations during off-peak energy consumption periods. The pricing periods can run for up to 10 hours a day, although it tends to vary depending on seasonality. However, low off-peak pricing may not help you much if you are a cold storage operator who needs a near-constant refrigeration solution. It may be challenging to avoid consumption during the costly peak hours entirely. The alternative is to implement TES technology to enable you to run operations for a few hours during high priced peak times of the day and shift the bulk of your operation to low priced times of the day

Key Takeaway

For any cold storage facility to run effectively and provide high performance at low costs, effective energy management is necessary. Operators need to prioritize strategies that guarantee equipment runs as intended while consuming less energy.

Article 2.

WHAT ARE THE MOST ENVIRONMENTALLY FRIENDLY REFRIGERANTS?

Common refrigerants used in commercial cold storage systems include hydrofluorocarbons (HFCs), hydrochlorofluorocarbons (HCFCs), and natural refrigerants like ammonia, carbon dioxide (CO2), and hydrocarbons. Natural refrigerants are gaining popularity due to their lower environmental impact.

What refrigerant is used in cold room?

Ammonia is generally used in centralized refrigeration systems that utilize a special machine room specifically installed for industrial or large-scale refrigeration systems that employ over 10,000 tons of cold storage. Freon is most commonly used in small and medium-sized cold room refrigeration systems.

How Does Refrigerant Work?

The refrigerant starts as a liquid in an air conditioner compressor and transitions into a gas under high pressure. The refrigerant gas flows into the condenser and releases its heat. While the refrigerant returns to a lower pressure rate, evaporation releases the cool air.

Which Refrigerants are Used in HVAC/R Systems?

R-134A – also known as Tetrafluoroethene (CF3H2F) is more ozone friendly and was used to replace R-12 CFC refrigerants. However, due to global warming issues, countries have banned R-134A.

R-143A – Trifluoroethane, a mixture component of R-404A refrigerant. R-143A is non-toxic and does not cause corrosion.

R-404A – a blended hydrofluorocarbon (HFC) that is nonflammable with low toxicity and is comprised of R-125, R-134A, and R-143A. R-404A works well in low to medium temperatures in refrigerated vehicles and ice makers.

R-410A – also known as Puron it is a chlorine–free refrigerant with higher heat absorption making it more efficient than previous refrigerants.

R-427A – Forane is a mixture used to replace rR-22 in low, medium, and high temperature cooling and air conditioners.

R-434A – a non-flammable HFC mixture used to replace R-22 refrigeration

R-502 – phased out in 1995, it was used in commercial refrigeration systems.

R-507A – also known as Genetron, it is a zero ozone depletion azeotropic HFC refrigerant.

R-717 – a refrigerant grade ammonia used in low to medium temperature refrigeration.

R-290 – is an eco-friendly refrigerant grade propane that is an alternative to R-22 and R-502, this refrigerant is used in all temperature usage for refrigeration and air-conditioning applications.

R-450A – also known as Solstice, it is an eco-friendly Zeotropic blend of R-134A and HFO-1234z. It is a non-flammable alternative to R-134A in medium temperature systems.

There are a few refrigerants that are used in refrigerators and HVAC systems.

Some newer refrigerants offer more environmentally friendly properties, including

R-32 – significantly more environmentally friendly than R-410A because it has a much lower Global Warming Potential.

R-513A – also known as Opteon, it is a next generation non-ozone depleting, low global warming potential hydro-fluoro-olefin (HFO) that replaces R-134A.

R-600 – an efficient natural refrigerant suitable for refrigeration applications. It is environmentally friendly and efficient.

_______________________________________________________________________________________________________

Article 1.

,WHAT ARE THE MOST IMPORTANT SAFETY PROCEDURES FOR SHIPPING FOOD PRODUCTS?

Shipping food products is a critical part of the food manufacturing process, as it ensures that the products reach the customers in good condition and comply with the relevant regulations. However, shipping food products also involves various risks and challenges, such as contamination, spoilage, damage, theft, and liability. Therefore, it is essential to follow some important safety procedures for shipping food products, both to protect the quality and safety of the products and to prevent any legal or financial issues. In this article, we will discuss some of the most important safety procedures for shipping food products, such as:

1 Choosing the right packaging

The first step in shipping food products is to choose the right packaging for the type and characteristics of the products. The packaging should be able to protect the products from physical, chemical, biological, and environmental hazards, such as shock, vibration, temperature, moisture, oxygen, light, insects, rodents, and microbes. The packaging should also be suitable for the mode and duration of transportation, such as air, sea, road, or rail. The packaging should also comply with the labeling and documentation requirements of the destination country, such as nutritional information, ingredients, allergens, origin, and expiration date. The packaging should also be easy to handle, stack, and load, and should minimize waste and environmental impact.

2 Maintaining the cold chain

The second step in shipping food products is to maintain the cold chain for the products that require refrigeration or freezing. This system of keeping the products at a constant low temperature throughout the distribution process is essential for preserving quality, safety, and shelf life, as well as preventing the growth of harmful bacteria and pathogens. To ensure the cold chain is maintained, insulated containers or refrigerated trucks should be used to transport the products. Additionally, temperature indicators and sensors should be employed to monitor and record the temperature of the products and containers at regular intervals, while also alerting any deviations or fluctuations in temperature. Moreover, direct sunlight and heat sources should be avoided, and the time and frequency of opening and closing containers or trucks should be minimized. Lastly, it’s important to adhere to the first-in, first-out (FIFO) principle in order to rotate stock and avoid spoilage.

3 Implementing hygiene and sanitation practices

The third step in shipping food products is to implement hygiene and sanitation practices for the personnel, equipment, and facilities involved in the shipping process. These practices are essential for preventing cross-contamination, pest infestation, and foodborne illness. To do this, personnel should be trained and educated on the proper handling, storage, and transportation of food products. Additionally, the use of personal protective equipment (PPE), such as gloves, masks, hairnets, and aprons should be provided and enforced. The equipment and facilities should also be cleaned and disinfected before and after each use. Furthermore, raw and cooked products, as well as allergenic and non-allergenic products should be separated. Damaged, spoiled, or expired products should be disposed of properly. Lastly, the Hazard Analysis and Critical Control Points (HACCP) system should be followed to identify and control any potential hazards in the shipping process.

4 Securing the cargo and the vehicle

Securing the cargo and the vehicle is the fourth step in shipping food products and is essential for ensuring the integrity and traceability of the products, as well as avoiding any liability or legal issues. To do so, you should use appropriate loading and unloading methods and equipment, such as pallets, forklifts, and ramps. Additionally, straps, locks, seals, and labels should be used to secure the containers or trucks. Furthermore, you should check and verify the weight, quantity, and condition of the products before and after each shipment. Keeping a detailed record of the shipment information such as date, time, origin, destination, driver, and vehicle is also important. In addition to this, GPS tracking or other technologies can be used to monitor the location and status of the shipment. Finally, any incidents or irregularities should be reported to the relevant authorities or parties.

5 Following the regulations and standards

The fifth step in shipping food products is to adhere to the regulations and standards that apply to the products and the destination country. This is essential for ensuring compliance, safety, and avoiding any fines, penalties, or rejections. The Food Safety Modernization Act (FSMA) regulates the safety of food products in the United States, while the International Organization for Standardization (ISO) sets standards for quality, safety, and environmental management of food products. The Codex Alimentarius is an international collection of guidelines and codes of practice for food products. Additionally, you must consider the specific rules and requirements of the destination country, such as customs, tariffs, inspections, certifications, and permits. Shipping food products requires meticulous planning, preparation, and execution. By following these important procedures for shipping food products, you can guarantee your products reach customers in optimal condition and quality, while also complying with applicable regulations and standards. This will help you improve your reputation, customer satisfaction, and profitability in the food manufacturing industry.