HOW SUPPLY CHAIN MANAGERS CAN HELP THEIR BUSINESS RECOVER FROM COVID-19.

The COVID-19 pandemic is negatively affecting the global economy, and supply chains are especially affected. The Institute of Supply Management’s surveyassessing the short- and long-term impacts of the outbreak shows that nearly 75% of businesses report supply chain disruptions due to transportation restrictions related to COVID-19. The survey further highlighted that 16% of these businesses plan to reduce their revenue targets by 5.6%.

Given the complexity of the situation, the recovery—specifically in supply chains—will likely require unprecedented levels of orchestration. The next few months are going to be challenging.

TIPS TO HELP YOUR BUSINESS RECOVER

Preparing your supply chain business for recovery, even as the crisis continues to unfold, will help you bounce back quickly and firmly. The actions you take during this recovery period will set the foundation for sustained, long-term growth.

1. Conduct Risk Assessments

Your short-term priorities should be responsiveness and speed. However, for long-term business continuity, you will have to proactively engage your supply chain partners, such as suppliers and logistics providers, to conduct a business risk analysis.

2. Develop a Risk Management Process

Map out your supply chain networks from the suppliers to the end customers. For each supply chain, establish a method to measure potential risk.

3. Leverage Technology

Use automation to streamline your supply chain and mitigate reliance on labor-intensive processes. For instance, logistics businesses should consider using a map route planner to reduce drive time, cut costs, and increase drivers’ productivity.

4. Assess Logistics Capacity

As you look to ramp up your business’s value chain, assess your existing logistics capacities to mitigate exposure to potential cost increases. Collaboration is an effective strategy to increase logistics capacity and improve contingency planning.

5. Mitigate Supply Shock

Another short-term goal should be to work with your existing suppliers. However, you should also use this time to identify potential suppliers that could diversify your supply chain and safeguard against shortages and future crises. Think of this pandemic as another reason to consider introducing supplier flexibility to your system.

The COVID-19 pandemic has disrupted all major supply chains with varying degrees. It is time for businesses to assess, recover from, and respond to the numerous challenges that still stand in the way. However, building a resilient supply chain that can withstand all potential epidemics should be your ultimate goal.

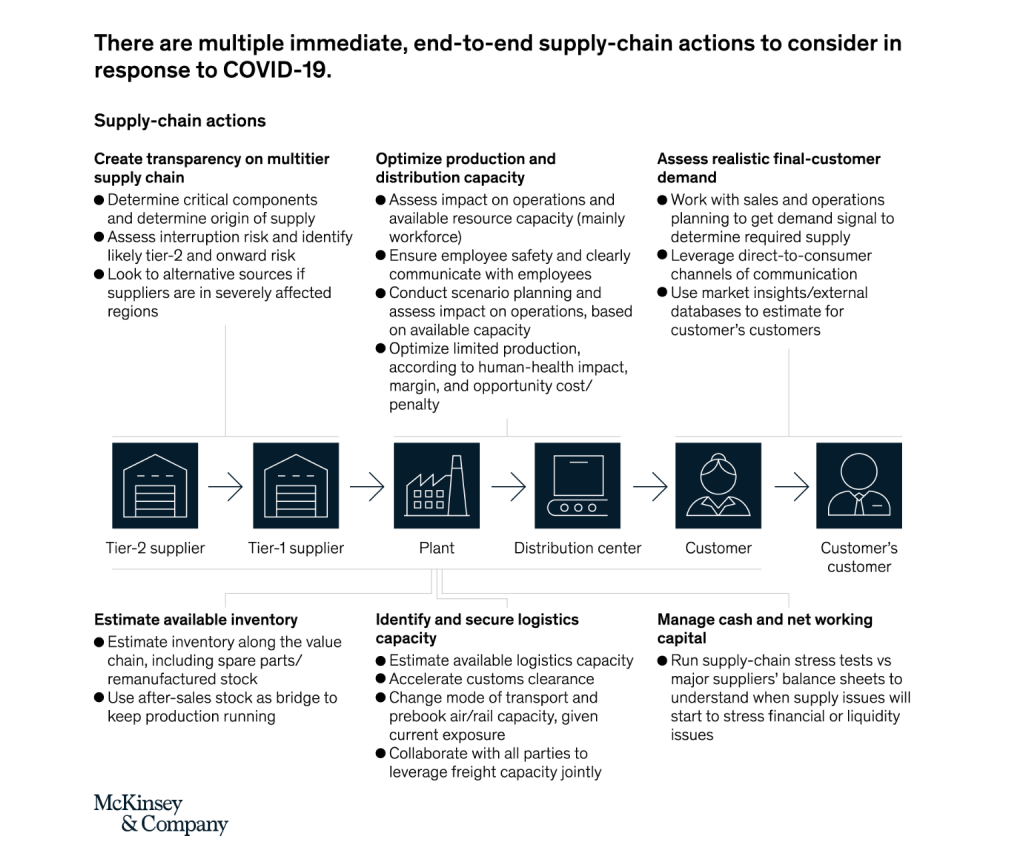

According to Mc Kinsey Company, this figure explains its strategy and how to make a good plan. (Source: Dan Khasis, CEO & Founder Route4me, edited and added by Hasanuddin Yasni, ARPI).